I’m lucky enough to call St. Andrews in Scotland my home. A home famously shared with one of the world’s favourite sports.

Every year, thousands of golf fans make the pilgrimage to St. Andrews to visit the birthplace of the challenging-but-rewarding game of golf.

Just like golf, supply chain planning carries its own obstacles and rewards — long-term plans do not always translate into reality in the way we expect — and we must course correct to accommodate where things don’t go quite according to plan.

While this can be a challenge, it comes with the satisfaction of having created a plan and managed through the exceptions to, ultimately, result in sales and service to our organisation’s customers.

I’m no golf expert, but even I’m aware that the cumbersome bag of various sticks carries a variety of tools each designed for a specific purpose. Within them lies:

- The Driver — The most impressive club in the bag allowing you to send the ball far down the fairway toward your goal. It can cover great distances but can also be the least precise.

- The Wedge — A club that can make or break your round. This club is used for your final approach to the green when your target is tantalisingly close. Maybe not as exciting as the big driver, but arguably more important to your round.

And planning processes are just the same:

- S&OP — Good for medium-term plans, broad brush in nature and allows planning to trade off supply and demand where there are relatively limited constraints within the supply chain due to the long time horizons.

- S&OE — Needs to be targeted in its approach in terms of the time and variability it can manage. Good for quick, short-term decision-making where options are limited.

Creating the Links

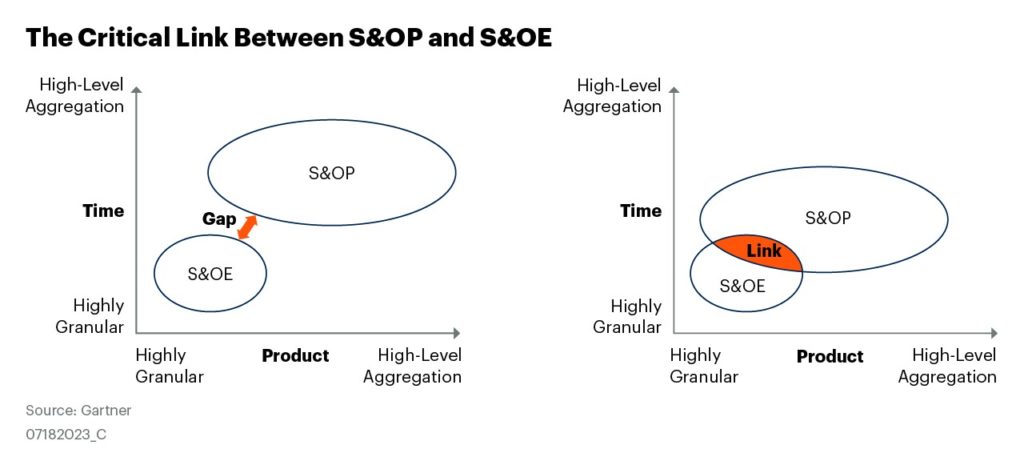

A lot of clients who have implemented S&OE approach us for help honing their “short game.” But when looking for the best performance gains, we often discover that the missing piece is how well-linked it is to their S&OP process.

If you’re feeling like there’s a disconnect between the long and short game in your supply chain planning processes here are a few areas worth looking at for opportunities to improve the links.

Continuity in Decision Making

Ensuring alignment between the decision-making principles used in S&OP and S&OE is critical to ensuring the processes are well-linked. Tactics to help ensure this include:

- Using a delegate or a direct report of your S&OP decision maker to chair the S&OE meetings. Make sure that the S&OE decision maker’s role in the organisation allows them to make unbiased decisions so that the best overall outcome can be achieved where trade-offs in the short-term need to be made.

- Focusing S&OP decision-making on principles and rules, as opposed to numbers, provides clarity and context to the S&OE forum. Overt communication of these decision-making principles and priorities provides direction for short-term trade-off decision-making.

Structuring the Team for Success

Also, think about your organisational structure, and whether it’s setting you up for success. For strong links between your short- and mid-term plans, you need to ensure strong links between the teams planning these horizons.

- Some companies have separate roles, or teams, to plan the short- and the mid-term, whereas others have teams responsible for the full-time horizon. The first organisational approach ensures that there is a dedicated resource focusing on the midterm.

This reduces the risk of the planning organisation constantly being drawn into short-term, reactive planning. However, it does introduce an organisational boundary which needs to be carefully managed to ensure there is not disconnect between the short- and mid-term planning teams and the plan. - If your planning organisation is structured by time horizons, ensure reporting lines between teams managing the S&OE and the S&OP horizons of the plan join at operational levels, relatively low down the organisation. This reduces the risk of disconnect and friction.

Underpinning Feasibility by Using Assumptions

While the plan created in S&OP does not need to be perfect, it does need to be feasible in its achievability, from both a demand and a supply perspective. Plans moving into the S&OE horizon that are over-optimistic, be it in terms of sales, yield or supplier-delivery performance, is a sure-fire way to inject volatility into the short-term.

- Focusing on assumptions as the building blocks for both the demand and supply elements of your S&OP plan is a great way to inject feasibility. Assumptions provide supply chain planning with the language to drive x-functional consensus around how past performance, overlaid with future activities, will translate into a plan that’s realistic.

For example, from the demand side of the equation, assumptions could include the impact of advertising or promotional activity on sales. From the supply side, transportation lead times or QA throughput capacity. - By underpinning the forecast with assumptions, where there are out-of-plan exceptions in the S&OE time horizon, planners can check back to the assumptions to see which were incorrect. These new insights can, in turn, be fed back into the S&OP plans to refine and improve the accuracy of future supply chain plans.

Having strengthened your supply chain by aligning your S&OP and S&OE processes you will now find you’re reaching the green far more consistently. All that’s left now is to execute and transact the plan. In other words, it’s time to grab your putter and start sinking some putts.

To take a deeper dive into S&OP and S&OE, Gartner clients can review:

Video: How Can I Build Stronger Links Between My S&OP and S&OE Process?

Build a Distinct S&OE Process That Is Aligned to S&OP

First published on Gartner Blog Network