The industrial sector is responsible for 21% of global CO2 emissions, releasing more than 9 gigatons of CO2 per year, driven primarily by emissions from the cement, chemicals, and steel sectors.

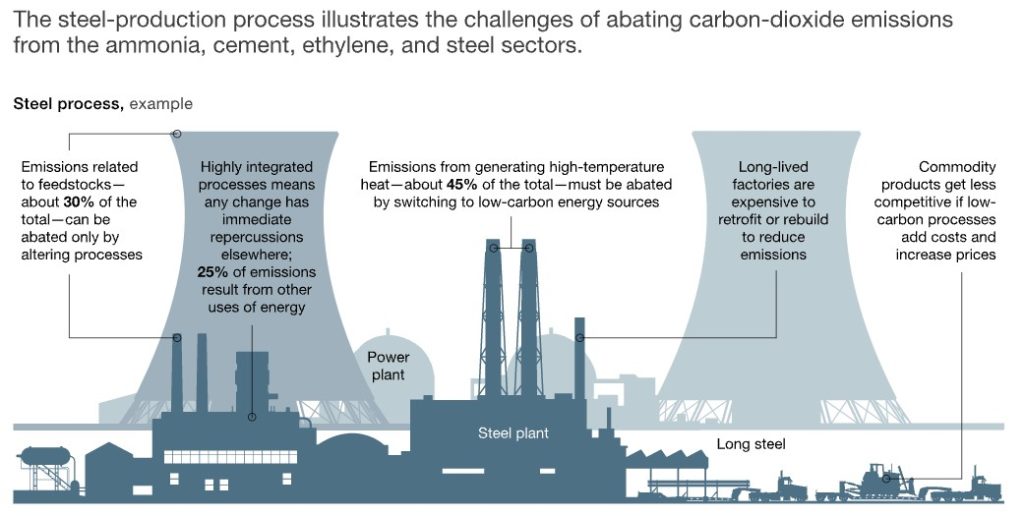

Abating CO2 emissions is harder than it seems, according to McKinsey which cited four technical reasons (Figure 1).

“First, the 45% of CO2 emissions come from feedstocks that cannot be abated by a change in fuels. Second, 35% of emissions come from burning fossil fuels to generate high-temperature heat.

Reducing these emissions by switching to alternative fuels, such as zero-carbon electricity, would be difficult because this would require significant changes to the design of furnaces.

Third, industrial processes are highly integrated, so any change to one part of a process must be accompanied by changes to other parts of that process.

Finally, production facilities have long lifetimes, typically exceeding 50 years with regular maintenance. Changing processes at existing sites requires costly rebuilds or retrofits.” How industry can move toward a low-carbon future, McKinsey

Decarbonizing the cement, steelmaking, and chemicals industries alone will cut global industrial emissions by half, but these industries are projected to continue growing for the long term.

Therein lies the challenge for the industrial sector: How can carbon neutrality be attained while meeting the increasing demand for products?

Building a roadmap for the decarbonization of industry is a complex endeavour that requires a deep understanding of the technologies available today as well as in the future to adequately prepare for tighter regulations in an increasingly competitive market.

Lux Research’s new report, Decarbonization of Industry: The Path Toward Carbon Neutrality, introduces a framework for assessing the technologies for decarbonizing industry and defines the challenge that entails by categorizing its carbon reduction technologies according to their complexity and ease of adoption.

Decarbonization technologies can be split into three levels of complexity:

Makeshift technologies reduce emissions without altering the key stages in the industrial process. These technologies decarbonize by tackling efficiency gaps, the carbon intensity of the feedstock, or the emissions released at the end of the process – the core technologies and fundamentals of the industrial process remain unchanged.

Retrofit technologies reduce emissions by altering one or more key stages in the industrial process. These technologies decarbonize by adding or swapping core process units with new, low-carbon variants that fit within the existing process flow. The fundamentals of the industrial process, however, remain unchanged.

Transformational technologies reduce emissions by altering the fundamentals of the industrial process. These technologies decarbonize by eliminating core incumbent process units and completely transforming the existing industrial process flow – these changes typically include replacing thermochemical platforms with biochemical or electrochemical platforms.

Runeel Daliah, senior analyst at Lux Research and lead author of the report, says these levels of technologies are the building blocks of industrial decarbonization.

“Although we talk about industrial decarbonization as a single concept, there is no monolithic solution to the industry’s problem; industrial decarbonization is realized through the bit-by-bit application of diverse technologies that are unique to specific industries and their core processes,” he continued.

Complex challenges ahead

Decarbonization of industry is complex – an industrial plant requires high investment, often to the tune of billions of dollars, and is built to last several decades.

As companies pledge to reach carbon neutrality by 2050, they are under significant pressure to transition from the thermochemical platforms they have been reliant on for the past three centuries to transformational technologies in just three decades.

There are competitive concerns for industrial products. If there are no regulations promoting the adoption of low-carbon products at the consumer end, decarbonization will reduce an industrial player’s competitiveness in the regional and global market.

Financial penalties on fossil-based manufacturing are not enough to support the decarbonization of industry – incentives for the import and consumption of low-carbon products within one’s borders are also necessary for a global transition to a carbon-neutral industry.