Leaders throughout history, from Abraham Lincoln to John F. Kennedy, have recognized that during every crisis, lies great opportunity. Or, as Winston Churchill famously said, “Never let a good crisis go to waste.”

Crises — and the disruptions they cause — are painful but can also present us with all sorts of possibilities. They force us to change, and those changes may be short-lived and minor, allowing us to return to business as usual.

Or they can be large-scale and systemic, requiring major changes. As is the case for many countries and industries — and the supply chains that connect them — the disruptions over the past few years have been significant and persistent.

As a result, organizations, and the supply chains supporting them, need to make major (i.e., transformational) changes.

We’ve dealt with disruptions in the past, but the frequency and severity of them have increased and become more widespread. As my colleague Suzie Petrusic described in her blog Dealing with Disruption, events such as Brexit, changes to US tariffs and the COVID-19 pandemic are unfamiliar and they cause major disruptions.

As she aptly said, “…the traditional constraint playbook for the supply chain is insufficient to respond to the situation facing supply chains today.” Another way to view her point is that incremental, continuous improvement will not be enough to avert disruptions.

Transformation is required. Many believe the transformation involves the implementation of technology, but it’s more than that. Gartner defines supply chain transformation as, “the coordinated implementation of various integrated initiatives across multiple supply chain functions that are sustained over time.”

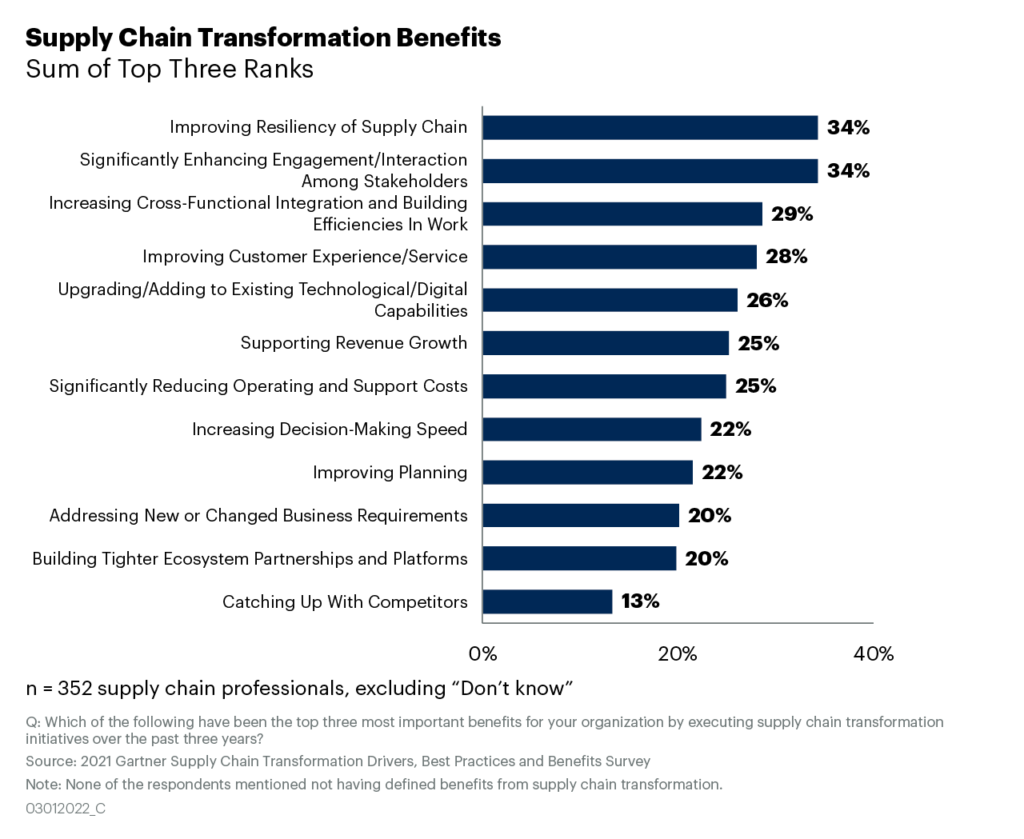

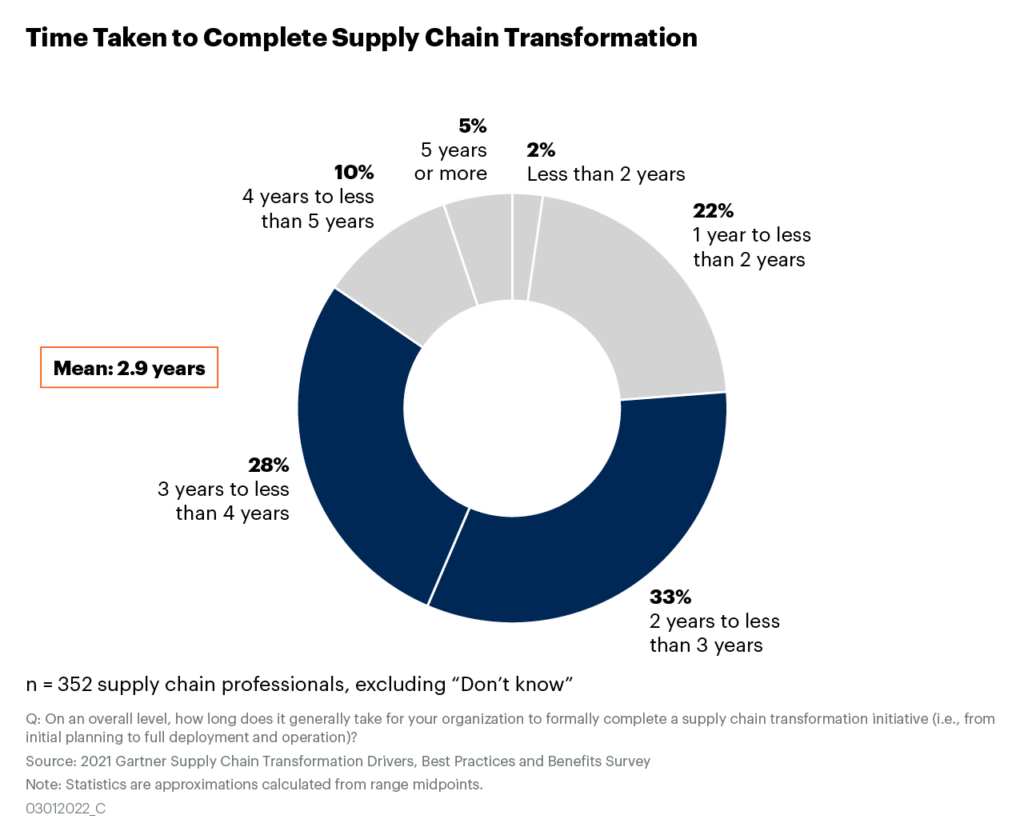

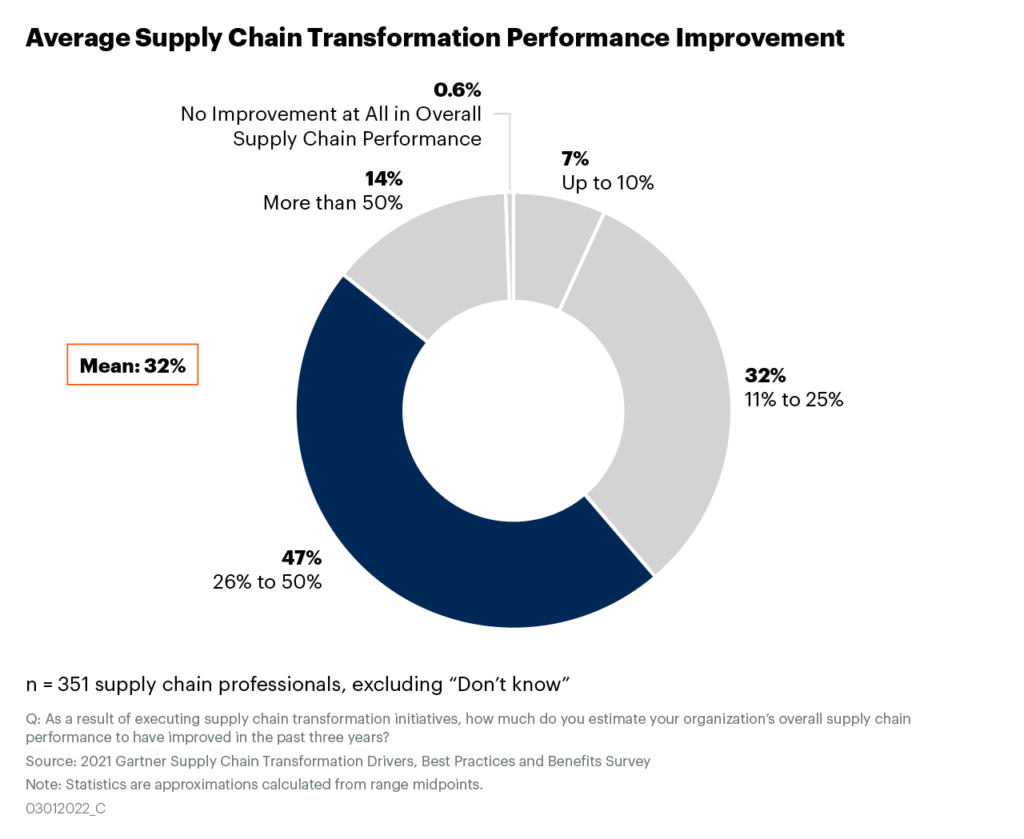

We augmented our supply chain transformation research in 2021 with a quantitative study examining transformation drivers, best practices, challenges, enabling technologies and benefits. The survey of 352 organizations in multiple countries and industries revealed the top benefits, time frames and performance improvements driven by supply chain transformations.

Benefits of transformation

Improved resiliency and agility help organizations better manage disruption. Our study indicates that better navigating disruptions were a key benefit that organizations hoped to realize from their supply chain transformations: 34% of respondents ranked improving supply chain resiliency to support agility as one of the top three most important benefits experienced over the last three years.

Time to complete transformation

We also asked how long it takes to transform the supply chain. Our research and advisory work with supply chain clients over the years led us to believe that transformation is a multi-year effort.

The data from the study supported that hypothesis. It showed that most — 76% — of transformations take more than two years to complete and that on average they take 2.9 years.

Performance improvement

CSCOs and supply chain leaders often ask us, “How much benefit should we expect from our supply chain transformation?” The answer is always, “It depends.” Factors such as current performance, ability to change and leadership all impact performance improvement and management.

Nonetheless, we felt it important to arm supply chain leaders with data to help them support their case for transformation. We asked respondents how much performance improved considering revenue, market/competitive position, growth and other supply chain KPIs.

The vast majority, more than 90%, of participating organizations reported double-digit improvements. And, on average, organizations estimated that their overall performance improved by 32%.

The shocks to our supply chains have been painful, but they also represent a unique opportunity. For decades we’ve struggled to get funding for supply chain initiatives. But now we are in the spotlight and should make the most of it.

We can — if we can obtain the resources and commitment required to remake our supply chains to be more resilient and agile. To do this, we must build a compelling transformation business case that is approved as a formal multi-year program with a dedicated budget and resources.

That is precisely what we heard for those that have completed a supply chain transformation in the last three years. Of those we surveyed, 68% agreed that a supply chain transformation is a formal program with a budget and dedicated resources, having a clear trigger, beginning, middle and end.

Building and improving capabilities to drive improved resiliency and other benefits takes time — about three years — but can drive significant benefit, on average 32% improvement in supply chain performance. We hope this data will be helpful as you build your supply chain transformation business case.

First published on Gartner Blog Network