Since the pandemic started in 2020, supply chains have struggled to keep logistics costs under control while also ensuring they retain adequate access to capacity.

As a result of macroeconomic factors, logistics costs are increasing across multiple transportation modes for many organizations. Modes such as air freight, ocean freight, full truckload, less-than-truckload and parcel costs are all on the rise. While the anticipated cost increase across each mode varies heavily, when viewed holistically, the total increase to an organization’s logistics budget presents a tremendous financial challenge with which supply chains must cope.

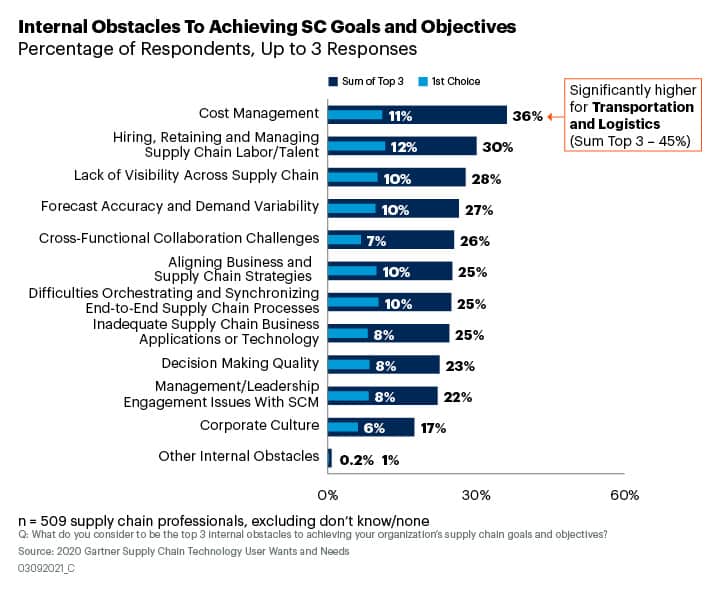

In the Gartner survey below, we asked organizations what their top internal obstacles were in achieving their goals. More than one-third (36%) of participants responded with “cost management” as one of their top three obstacles in achieving their supply chain goals and objectives. When looking at responses from individuals in transportation and logistics, that percentage increases to 45%.

Therefore, supply chain leaders will certainly have their work cut out for them this year to keep those rising costs under control to meet the strategic imperatives of their organization. To minimize the impact of cost increases on logistics services, a two-pronged approach focusing on both the external and internal cost factors is needed.

When tackling the first prong — external cost factors — the primary focus is on external negotiations with logistics providers. Organizations are carefully considering which providers they should invite to tender for logistics services. For many supply chains, 2020 was a litmus test for the relationship between shippers and logistics providers.

The challenges of 2020 created a stark contrast between the reliable and unreliable provider and helped give shippers insight into the true meaning of strategic partnerships in outsourcing. While past performance in 2020 will certainly be taken into consideration in provider selection, cost increases require more of a data-driven approach to determine what is “fair” given the most current market conditions for each mode.

Using a Data-Driven Approach to Drive Negotiations

Supply chain leaders should leverage the use of benchmarking and market intelligence platforms to monitor rapidly changing market conditions and conduct lane rate benchmarking when possible, before contract negotiations. Using these kinds of services empowers organizations to gain market transparency and establish justifications for potential contract rate increases.

Benchmarking and marketing intelligence platforms have become essential tools required for supply chain leaders to make informed decisions concerning contract pricing and rate negotiations. Those that do not use the data-driven platforms and tools available are more likely to experience frustration during negotiations from not benefiting from those insights. Furthermore, being uninformed on market conditions may result in supply chain leaders leaving money on the table when closing negotiations.

Shifting Focus to What You Control Internally

In addition to external negotiations, the second prong to this approach is the internal piece. Getting a handle on your logistics costs requires taking a hard look at your internal operations and identifying ways to drive cost savings through operational improvements. Performance benchmarking should be done internally to identify areas that could benefit from the most improvement. If you’re not conducting performance benchmarking, knowing what “good” looks like and how your organization compares can be difficult to determine.

Fundamentally, driving waste out of operations can be highly effective in achieving cost savings in logistics within a short time frame. Below are just a few examples of cost-saving initiatives many shippers have leveraged internally and have realized substantial cost savings from:

- Eliminating unnecessary expedited shipments

- Reducing intercompany transfer costs through consolidation efforts

- Reducing inventory repositioning costs from one distribution centre to another

- Setting shipping cost avoidance targets for suppliers/manufacturers to promote cargo consolidation efforts at origin

Leveraging the services of a freight audit and payment provider to audit carrier invoices and reduce overpayments as a result of invoicing errors

The above list is not meant to be all-inclusive, but rather illustrative of the kinds of initiatives that can result in cost savings through operational improvements in logistics. Each organization is different and will, of course, have its own set of unique initiatives that can be leveraged to achieve similar outcomes to help free up cash and help improve cash flow.

If you’re wondering where to look for more customized initiatives for your organization, look no further than your employees. Often the best ideas for how to improve operations and generate cost savings come from the individuals who directly participate in the day-to-day activities of your organization.

First published on Gartner Blog Network