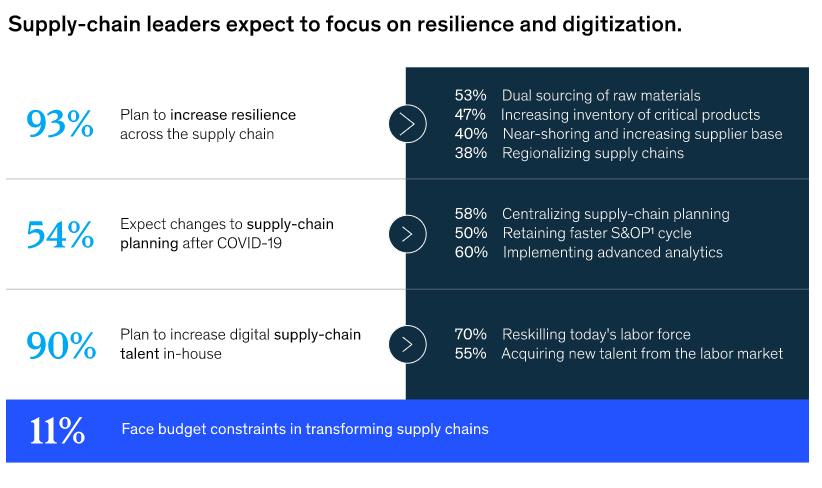

In Q2 2021, McKinsey surveyed supply-chain leaders to ascertain steps taken to shore up supply chains since the start of the pandemic. Ninety-two per cent confirmed having made changes to their supply-chain footprints resulting in improved resilience.

With 2022 just days away, what can we expect in 2022?

James Christopher, president – Asia, TMX warns that the Omicron variant could impact the supply chain in several ways. Depending on the global spread of the variant, it could impact a business’ ability to source their products or raw materials for their products, at a time when supply chains are still ‘catching up’ from the delays over the past two years.

While acknowledging the difficulty of predicting the future, Pieter J Els, senior director, cloud applications development for JAPAC at Oracle, says the chaos seems to be in line with the ‘never normal’ is now the norm. “The pandemic continues to force supply chain companies to reassess their priorities and how they apply the latest technologies for supply chain management optimisation,” he continued.

Importance of visibility in 2023 and beyond

One of the key vulnerabilities highlighted during the pandemic was the lack of visibility of many parts of the supply chain.

The McKinsey supply chain survey revealed that risk has moved to the top of the corporate agenda with 95% of respondents acknowledging now having a formal supply-chain risk-management process. A small per cent (4%) have set up a dedicated risk-management function from scratch while most have strengthened existing capabilities.

Oracle’s Els said to address resilience and risk, real-time visibility has become crucial to the supply chain.

“Real-time visibility allows businesses to have a comprehensive risk approach that can drive rapid and strategic decision-making when supply and demand become unbalanced,” he added.

Digitalization of the supply chain

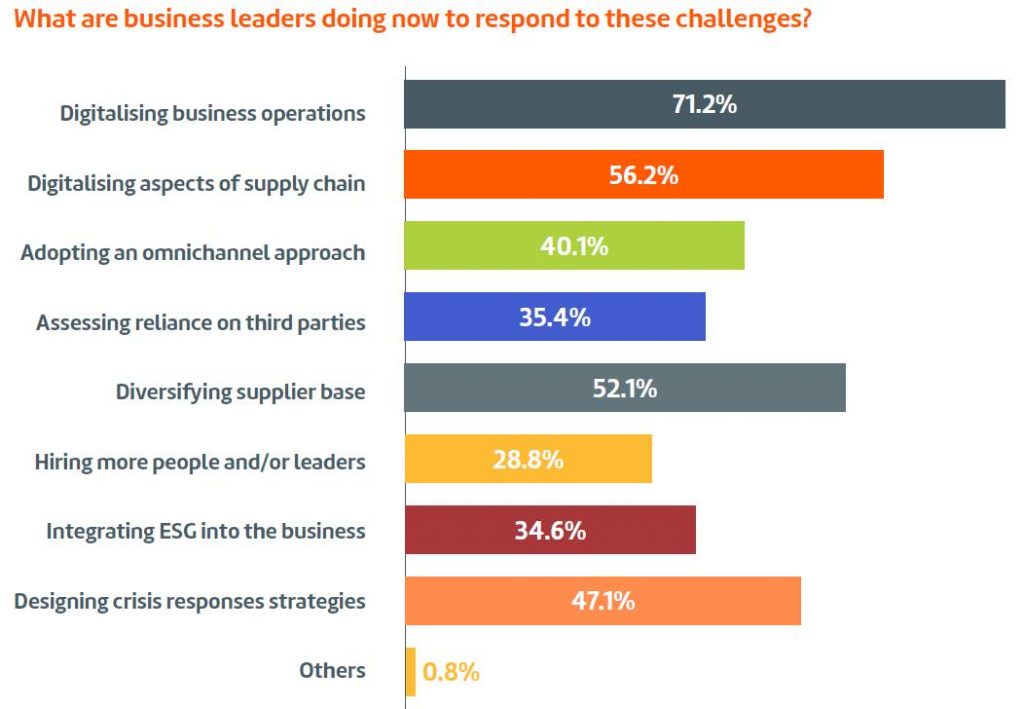

According to TMX’s ‘Building Back from the Pandemic: A Look into Supply Chains in the New Normal’ report, business leaders in the region are expecting to see the continued acceleration of digitalisation in 2022 and beyond.

Christopher said businesses will be looking at synchronising their physical and digital supply chains to have full end-to-end operational visibility.

“Such interconnected systems will enable real-time analytics for rapid data-backed decision-making that allow businesses to be flexible and responsible, especially in the face of ongoing disruptions,” he added.

For Vivek Luthra, supply chain & operational leader for growth markets at Accenture, the scale of unprecedented supply chain delays and disruptions is greater than ever before, and businesses can no longer afford to be caught off-guard or play catch-up.

“In response, organizations are racing to increase visibility over their end-to-end supply chain operations — bridging siloed functions, and investing strategically in AI, ML, Cloud and IoT to enhance real-time predictability and intelligence, as well as integrated planning capabilities,” he opined.

Growing complexity

Despite advances in technology and process innovation, and perhaps even contributing to it, the supply continues to grow in complexity.

“Moving from a project view to a life cycle view of supply chain capabilities helps reduce, manage and benefit from complexity. CSCOs must reinvent the operating model so the as-is doesn’t become so ingrained that it prevents innovation,” said Jennifer Loveland, senior director analyst with Gartner.

Christopher noted that one of the key learnings from the pandemic is that businesses will first have to be flexible and agile in their operations and be open to adopting new solutions.

He posited that businesses will need to have all their internal and external supply chain systems interconnected to provide visibility in their whole value chain to provide real-time analytics for smarter decision-making, data-backed predictions, and more dynamic processes.

“Companies need to provide the tools that can help their workforce navigate the future of work. The combined power of cloud applications and artificial intelligence (AI) can help organisations innovate, simplify, and keep up with technological change,” said Els.

For his part, Luthra observed that supply chain leaders are investing heavily in automation (4x more than three years ago), and the use of data (2.5x more than three years ago) across their organizations.

“They are also building talent capabilities in areas like data science, to embrace new areas of working. All of this will be crucial to enhance the efficiency, predictability, profitability, and overall digital resiliency of supply chain operations,” he commented.

Best practices in resilience building

Circling back on the topic of resilience and sustainability, Christopher called out the TMX study which revealed that more than 70% of business leaders in the region see automation as key to helping them respond to the challenges of the pandemic.

“Diversifying their supplier base and going down the omnichannel route are also other important moves made by companies like ECCO and Schneider Electric. For instance, the former had its European business consolidate its retail and online business, while the latter sought to shorten their supply chains in regions like North America by building up capacity in nearby markets instead of focusing on further markets in Asia,” noted Christopher.

Els believed that sustainability is everybody’s business and needs to be part of corporate strategy, ensuring that everything that is done considers the end-consumer – the re-imagined customer experience.

He posited that customers and prospects must now evaluate (partner) companies through the sustainability lens. Companies are doing the same with their suppliers and partners, holding them accountable for their carbon emissions, renewable energy sources, waste from landfills, and other environmental concerns.

“As a best practice, sustainability efforts should not be driven by compliance and investor pressure, rather by strategic planning and risk management, and they should now be measurable,” he continued.

According to Luthra, companies are addressing this with 4 key priorities including adopting holistic supply chain strategies that minimize silos and maximize visibility; increasing collaboration across business and technology functions for operational agility; investing in tools and technologies that drive intelligent, real-time insights and data-driven decision-making; and fostering strong ecosystem partnerships that allow them to accelerate innovation at speed and scale.